Tank semi-trailers for the transport of liquid substances, dump trucks, storage and process tanks.

Semi - trailers can be produced on a self – supporting or frame option as well as stainless steel one.

We produce tankers for liquid foodstuffs transportation requiring heating systems and others – not subjected to ADR regulations.

The tankers are either supported by a full frame (full frame on 3-axle semi - trailer) or self – supporting ones (3 – axle semitrailer which gives mass reduction of ca. 600 kg).

General specification of semi - trailers:

• capacity up to 34.000 l

• circular cross section

• number of compartments – according to Customer’s needs (3 compartments as a standard)

• internal tank made of stainless steel i.e. AISI304, AISI316 , AISI316Ti

• external jacket made of stainless steel AISI 304, polished (so called”mirror”), BA, Aluminium or GFK

• bottoms made of plastic acc. to RAL colours palette

• top manholes with insulated covers equipped with vent valves

• supporting elements (rungs) made of stainless steel AISI 304 – in case of self – supporting semi – trailers and ordinary steel protection against corrosion in the hot – dip galvanizing process for frame of semi trailers

• insulated with mineral wool, styrofoam or polyurethane foam of 100 mm thickness

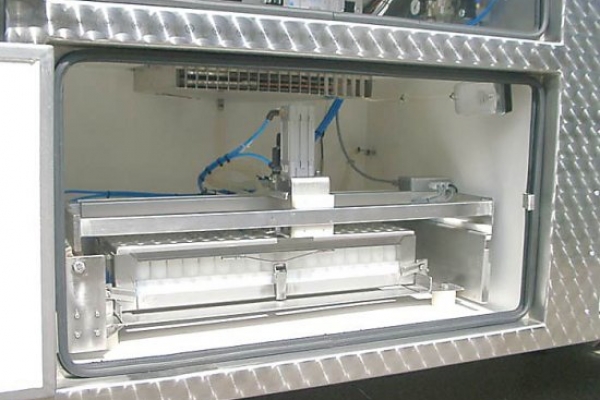

• central CIP cleaning system, washing head in each compartment, at each branch on the washing head the shut-off valve and/or designed to be washed at CIP stations

• optionally: for products demanding to be transported with a higher temperature (i.e. oil or chocolate) – heating system using independent heating unit or engine cooling system for a tractor unit

• temperature measurement by means of a clock temperature socket

• service platform with a handrail lifted by a ladder lever

Optionally:

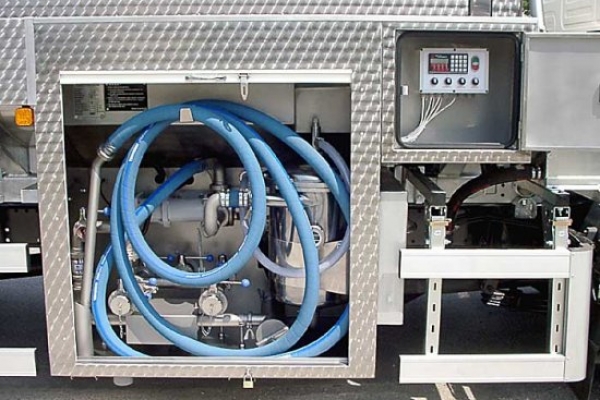

• transport containers for loading hoses

• transport hoses

• fender rails – side crossbars protecting the tank’s jacket against hoses while loading from the top

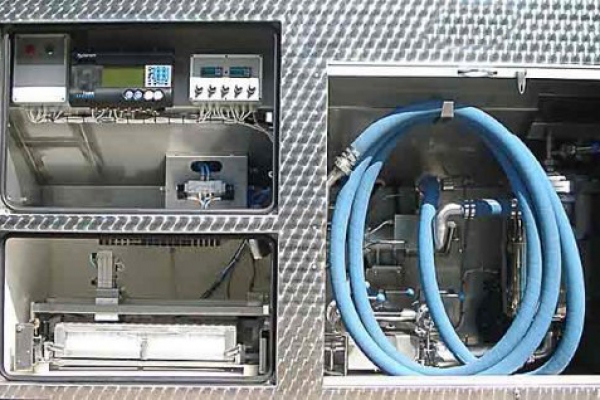

• pumps dedicated to unload the tank from the product: membrane, rotor, cam, pneumatic, electric or hydraulic drive

Optionally:

• pressure tank with the ability to be unloaded by air (Technical passport)

• ATP Certificate (Certificate of Conformity with the Agreement concerning International carriage of fast expiring food products and special means of transport used for these transports

• chassis – according to the Customer’s needs

TANKERS

Tankers are dedicated to milk transportation and other food products, we mount the tankers on appropriately complied 2-axle and 3-axle chassis.

capacity from 8.000 – 17.600 l

The material used to make the tank, external cladding and belts.

is stainless steel AISI 304.

The milk measuring system with PK-4.

Tiger (Bartec), MAK 3002 (Bartec), PD210 (Process data), PD4000 (Process Data), ARS Compact (Ebner), S12 (poul Tarp), Data transfer (USB stick, GPRS, Wi-Fi).

We do provide:

Central Office Measures Authorization; European Type Approval of the milk measuring system (according to the MID Directive); ATP Certificate: Certificate of Conformity with the Agreement on the International carriage of fast expiring food products and special means of transport used for these transports; National Institute of Hygiene Certificate.

We do fullfill the order according to the customer’s specification.

MuuMap

MuuMap is a system of navigation and transport organisation supporting and supervising the process of milk reception from various suppliers. It is possible to optimize routes and monitor the areas which are not included in the standard of navigation systems. MuuMap helps to reduce transport costs and ensures efficient use of rolling stock, increases time-keeping, provides the support for drivers who drive on a rough terrain and enables effective vehicles management.